- 01: Introduction

- 02: History

- 03: Propellants, Firearms, and Ammunition Development

- 04: Modern Firearms Manufacture

- 05: Small Arms Ammunition

- 06: Evidence Handling Procedures

- 07: Equipment and Instrumentation

- 08: Examination of Firearms

- 09: Cartridge and Shotshell Examination

- 10: Characterization and Evaluation of Fired Projectiles

- 11: Bullet Comparison and Identification

- 12: Gunshot Residue and Distance Determination

- 13: Toolmark Identification

- 14: Communicating Results

- Resources

Low-Stress Load Parts

Home > Modern Firearms Manufacture > Parts Fabrication > Low-Stress Load Parts

| Stress Loads | |

| High-Stress Load Parts: | Low-Stress Load Parts: |

Frame or receiver |

Lockwork or lock parts |

Slide |

Repeating mechanism components |

Bolt or breechblock |

Small pins, screws, and springs |

Cylinder |

Detachable magazines |

Low-stress parts present special manufacturing challenges due to their smaller size and the large variety and quantity required for assembly. The components may be part of the firing mechanism or lockwork, the repeating mechanism, or may be springs, screws, and pins for attaching other parts.

Lock Parts

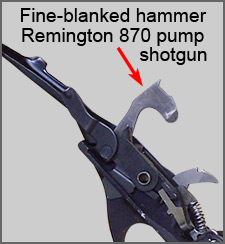

Although seldom affected by the pressure generated by a fired cartridge, hammers and triggers must withstand repeated shock of operation and recoil. The manufacturing process used depends on the final desired shape of the part. Hammers and triggers that are not considered a cosmetic item can be fine blanked. This is common in low-cost commercial rifles and shotguns and in some military arms. The precision of fine blanking requires minimal final fitting. The process is limited to parts that are essentially slab sided (uniform thickness) where appearance is not a major factor.

For example, one maker of quality revolvers fitted some of their most popular models with slab-sided hammers and triggers. However, their marketing image made stamped parts unacceptable. Before CNC was developed, the firm’s engineers developed a unique approach to economically create high-strength milled hammers and triggers. A solid bar of forged steel was progressively fed through several milling machines to create the complex side profile of these parts. Viewed end-on, the bar looked like the finished hammer or trigger, but was approximately eighteen inches (46 cm) long. The shaped part was fed into an automated saw; hammers and triggers were sliced off like salami. The parts needed only minor milling and drilling before being sent to finishing and assembly.

For hammers and triggers that vary significantly in thickness, forging was standard for years. Today, investment casting and/or powdered metal technology are replacing forging. Either process can easily produce cavities, steps, and recesses that would require machining in a forged part.

Smaller parts of the lockwork, such as a sear, safety, or disconnector device are usually complex shapes that do not lend themselves to low-cost fine blanking. They all require precision for safety. CNC milling is still common, but investment casting and PMT have both made inroads due to their ability to reproduce complex shapes.

Most firing pins are rod shaped and symmetrical. Turning on automated lathes is the preferred manufacturing method. A magazine is loaded with precut rods feeding work to a cutting unit. The rod is mounted, profiled to a set pattern, and unmounted in a controlled cycle. The use of a common cutter can produce coarse marks (known as subclass characteristics) that may repeat between pins. The wise examiner approaches concentric firing pin marks with caution.