- 01: Introduction

- 02: History

- 03: Propellants, Firearms, and Ammunition Development

- 04: Modern Firearms Manufacture

- 05: Small Arms Ammunition

- 06: Evidence Handling Procedures

- 07: Equipment and Instrumentation

- 08: Examination of Firearms

- 09: Cartridge and Shotshell Examination

- 10: Characterization and Evaluation of Fired Projectiles

- 11: Bullet Comparison and Identification

- 12: Gunshot Residue and Distance Determination

- 13: Toolmark Identification

- 14: Communicating Results

- Resources

Button Swaged

Home > Modern Firearms Manufacture > Rifled Barrels > Cut Rifling > Button Swaged

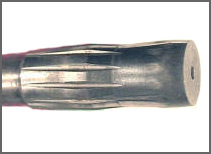

Double-tapered rifling button

Button-swaged rifling is one of two forms of swaged or cold-formed rifling. Metal is moved, not removed, to produce the pattern of lands and grooves.

A rifling button is a double-tapered metal plug; its largest diameter is roughly in the middle of the unit. The metal must be harder than the barrel steel, composed of either the best heat-treated tool steel or tungsten carbide. Tungsten carbide is preferred because its high density allows the button to glide smoothly over softer barrel steel, retaining the dimensions of the button longer.

In cross section, a rifling button is the reverse of the desired rifling pattern. High areas on the button press the grooves into the bore; low areas allow cooling fluids to circulate. Chip production is minimal. The button is pulled through the bore with a machine similar to that used for broaching or single-point rifling. The machine pulls the button through the barrel to produce the twist. Since the working surface area of a rifling button is small, building the twist into the button is not always required. Stressed steel springs back after the stress is removed; a rifling button is commonly slightly larger than the target value for groove diameter. Buttons are replaced when the depth of the rifling groove approaches the minimum specified groove depth.

Button-rifled barrels are durable and offer low cost and high production rates. The work hardening of the barrel steel caused by the button results in a bore surface that is denser than a cut surface. It is best for barrels that do not require deep rifling grooves. As a result, it is most commonly seen in .22 caliber barrels or pellet guns.

Drill and reamer marks are not removed by button rifling as they are with cut rifling. The marks are pressed into the grooves, and the highly polished button does not produce significant major unique marks unless the button is damaged.