- 01: Introduction

- 02: History

- 03: Propellants, Firearms, and Ammunition Development

- 04: Modern Firearms Manufacture

- 05: Small Arms Ammunition

- 06: Evidence Handling Procedures

- 07: Equipment and Instrumentation

- 08: Examination of Firearms

- 09: Cartridge and Shotshell Examination

- 10: Characterization and Evaluation of Fired Projectiles

- 11: Bullet Comparison and Identification

- 12: Gunshot Residue and Distance Determination

- 13: Toolmark Identification

- 14: Communicating Results

- Resources

Metal-Forming Operations

Home > Modern Firearms Manufacture > Metal -Forming Operations

Metal forming can be divided into two categories:gross forming and fine forming. Gross forming reduces raw metal stock to a rough form that is intermediate to the required shape. Fine forming renders the intermediate form to its final dimensions, with the exception of parts requiring hand fitting. Fine forming is discussed in a later section of this module.

Casting

Sand molds have been a mainstay of foundries for centuries. Molten metal is poured into a mold; the hollow interior is the negative of the desired part. The mold must be able to withstand the heat of molten metal.

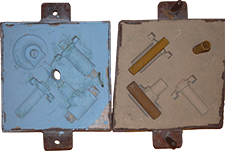

Cope & drag, with cores in place on the drag

Click for larger imageTraditionally, a master wooden pattern is created and packed in sand in two halves of a mold. The halves are known as the cope and the drag. The cope and the drag are separated and the wooden pattern removed. Molten metal is poured into the cavity through a sprue hole and allowed to harden. The cope and drag are separated and the part is removed for possible additional fine forming. Sand is recycled to be used for future molds. This process is known as casting.

Another casting method, known as the lost (sacrificial) wax process, does not require the removal of the wooden pattern. Instead, a sacrificial wax pattern melts and runs out of the mold; the mold retains the shape of the part as a cavity. Molten metal poured into the mold fills the cavity and cools to the same shape.

Wax or sand molds are broken away to release the newly founded metal part. Gun parts are not large and may be cast several at a time. Multiple parts can be cast in a single wax form and are connected by runners or gates as a means to distribute the molten metal evenly to the various parts. The tree-like metal casting is cut or broken at the runners to release the individual parts. Depending on the master pattern and how the mold is prepared, the resulting casting may have a rough surface finish.

Traditionally, ferrous alloys (containing iron) used for casting produced a rather brittle product. The slow cooling process creates loosely packed large crystals of iron (compared to other processes). As a result, cast iron gun parts are virtually obsolete, replaced by modern technology and materials.