- 01: Introduction

- 02: History

- 03: Propellants, Firearms, and Ammunition Development

- 04: Modern Firearms Manufacture

- 05: Small Arms Ammunition

- 06: Evidence Handling Procedures

- 07: Equipment and Instrumentation

- 08: Examination of Firearms

- 09: Cartridge and Shotshell Examination

- 10: Characterization and Evaluation of Fired Projectiles

- 11: Bullet Comparison and Identification

- 12: Gunshot Residue and Distance Determination

- 13: Toolmark Identification

- 14: Communicating Results

- Resources

Broaching

Home > Modern Firearms Manufacture > Fine Forming Operations > Broaching

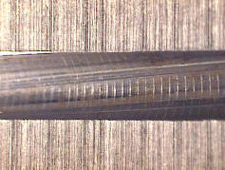

Rifling broach

Broaching uses multiple cutting surfaces (cutters) mounted on the same axis to progressively remove metal. It is used for critical operations where precise angle or depth control must be maintained. After the first cutter, each successive cutter is a few ten-thousandths larger than the one before it. Each cutter shaves off a small amount of metal, reducing the applied force.

Broached rifle barrel

Most firearm examiners will recognize the word broaching from its use in the manufacture of rifled gun barrels. Broaching is one way to produce the spiral grooves needed to spin-stabilize a bullet. A rifling broach has circular working nodes, each with a reverse profile of the rifling pattern. As the broach moves through the barrel, each node shaves off a little metal. The next node is slightly larger and rotated from the previous node to match the desired rifling twist. Broached barrels made with quality tooling have very straight bores and are capable of fine accuracy.