- 01: Introduction

- 02: History

- 03: Propellants, Firearms, and Ammunition Development

- 04: Modern Firearms Manufacture

- 05: Small Arms Ammunition

- 06: Evidence Handling Procedures

- 07: Equipment and Instrumentation

- 08: Examination of Firearms

- 09: Cartridge and Shotshell Examination

- 10: Characterization and Evaluation of Fired Projectiles

- 11: Bullet Comparison and Identification

- 12: Gunshot Residue and Distance Determination

- 13: Toolmark Identification

- 14: Communicating Results

- Resources

Physical Characteristics

Home > Toolmark Identification > Basic Toolmark Identification > Physical Characteristics

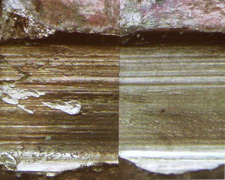

Subclass characteristics of a Ruger firearm -

cast of land impression #6 compared

with cast of land impression #1

The striated and impressed toolmarks may contain several levels of marks resulting from tool use on softer objects, including these:

- Class characteristics – measurable features of a tool that indicate a limited group source. They result from design factors and are therefore determined prior to manufacture. Common examples would be the width of the tip of a screwdriver, the width of the jaw of a gripping tool, or the kind of cutting action employed by a tool.

- Individual characteristics – marks on an object produced by the random imperfections or irregularities on the surfaces of the tools used to manufacture the object. These marks are produced incidental to the manufacturing process and are typically at the microscopic level. Individual characteristics can also be produced on an object by use, abuse, and the effects of random corrosion. To use the example of a screwdriver, individual characteristics could be found on the tip of a precision screwdriver by the process of finishing it using a grinding wheel. As a screwdriver is used, misused, and corrodes, it becomes more unique.

Note: Accidental characteristics is a term formerly used to mean individual characteristics. - Subclass characteristics – discernable surface features of an object that are more restrictive than class characteristics, but not as unique as individual characteristics. In the screwdriver example, subclass or family characteristics might be found on the tip of a few hundred inexpensive screwdrivers stamped out by a dedicated machine, with no further finishing. The class characteristics of this stamping machine would gradually change, but not before producing a potentially large number of screwdrivers with tips bearing similar subclass characteristics.

Subclass characteristics are - produced incidental to the manufacture of a tool,

- significant because they relate to a smaller group source, that is, a subset of the class to which they belong,

- identifiable within a time frame since manufacturing processes change over time.

Subclass characteristics may be a pitfall in the examination and comparison of toolmarks simply because they can appear to be individual characteristics. Examination of the evidence tool allows the examiner to assess the level of subclass characteristics.