- 01: Introduction

- 02: History

- 03: Propellants, Firearms, and Ammunition Development

- 04: Modern Firearms Manufacture

- 05: Small Arms Ammunition

- 06: Evidence Handling Procedures

- 07: Equipment and Instrumentation

- 08: Examination of Firearms

- 09: Cartridge and Shotshell Examination

- 10: Characterization and Evaluation of Fired Projectiles

- 11: Bullet Comparison and Identification

- 12: Gunshot Residue and Distance Determination

- 13: Toolmark Identification

- 14: Communicating Results

- Resources

Incidental Toolmarks

Home > Toolmark Identification > Basic Toolmark Identification > Incidental Toolmarks

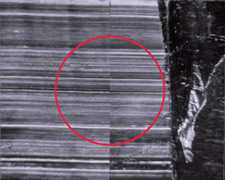

Identification of striated marks

Toothmark impression left by arcjoint pliers

Incidental marks are transferred by the operating surface of a tool making contact with the surface of a softer object. While class characteristics are planned by the manufacturer (e.g., width, shape, length), incidental marks (individual characteristics) are not planned and occur as a result of the manufacturing process as well as normal use of the tool.

These marks are as follows:

- Striated toolmarks (also called striae, friction marks, abrasion marks, or scratch marks) – produced when a tool is placed against another object and moved parallel to and across the object with pressure applied. The striations consist of the resulting surface contour variations.

- Impressed toolmarks (also called compression marks) – produced when a tool is placed against another object and sufficient force is applied to the tool to leave an impression. These impressions are contour variations left on the surface of the object by this interaction.

Both impressed and striated toolmarks may be produced by objects designed, manufactured, and marketed as task-specific tools or such tools misused for another purpose. Marks may be produced by other objects used as tools to gain a temporary mechanical advantage.