- 01: Introduction

- 02: History

- 03: Propellants, Firearms, and Ammunition Development

- 04: Modern Firearms Manufacture

- 05: Small Arms Ammunition

- 06: Evidence Handling Procedures

- 07: Equipment and Instrumentation

- 08: Examination of Firearms

- 09: Cartridge and Shotshell Examination

- 10: Characterization and Evaluation of Fired Projectiles

- 11: Bullet Comparison and Identification

- 12: Gunshot Residue and Distance Determination

- 13: Toolmark Identification

- 14: Communicating Results

- Resources

Crimping

Home > Small Arms Ammunition > Assembly > Crimping

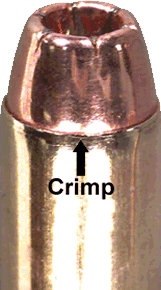

Crimping is the folding or bending of the case mouth to grip the bullet. For conventional bullets, this is a relatively simple operation because the case diameter is larger than the bullet diameter. A simple die with an internal shoulder can form the crimp quickly.

Crimped cartridge

This is not possible for rimfire bullets; a rotary crimper is used instead. Loaded cartridges fall onto a plate and are driven against a rotating steel wheel with protrusions that roll the crimp into the case and bullet at the correct location. Simultaneously, any cannelures (for the purpose of retaining lubrication) are rolled. For additional weatherproofing, a knife cut may be used to force lead onto the new crimp; this is also performed on the rotary crimper.

Lubrication is added to lead bullets to reduce bore fouling . Rimfire bullets can be prelubricated or lubricant can be added after the cartridge is loaded. The final steps are testing, inspection, and packaging of the loaded cartridges.