- 01: Introduction

- 02: History

- 03: Propellants, Firearms, and Ammunition Development

- 04: Modern Firearms Manufacture

- 05: Small Arms Ammunition

- 06: Evidence Handling Procedures

- 07: Equipment and Instrumentation

- 08: Examination of Firearms

- 09: Cartridge and Shotshell Examination

- 10: Characterization and Evaluation of Fired Projectiles

- 11: Bullet Comparison and Identification

- 12: Gunshot Residue and Distance Determination

- 13: Toolmark Identification

- 14: Communicating Results

- Resources

Other Jacket-Forming Technology

Home > Small Arms Ammunition > Projectiles > Other Jacket-Forming Technology

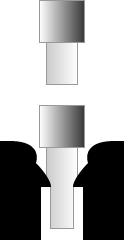

Impact extrusion process

Although the drawn jacket is still the most common method, newer technologies are emerging. Like coining, impact extrusion of jackets is performed in closed dies and can often produce a long rifle bullet jacket in fewer operations than required to draw the same jacket. Impact extrusion provides improved control over wall concentricity and produces a finished jacket edge.

Jackets can be formed through chemical electroplating, bonding the jacket to the lead core. Separation of the jacket from the core was once a major hindrance to bullet performance. The process of plating jackets was first used for fully encased jacketed handgun bullets. These bullets start as an alloyed lead core that is swaged from wire. The core is plated to build up a jacket of uniform thickness.