- 01: Introduction

- 02: History

- 03: Propellants, Firearms, and Ammunition Development

- 04: Modern Firearms Manufacture

- 05: Small Arms Ammunition

- 06: Evidence Handling Procedures

- 07: Equipment and Instrumentation

- 08: Examination of Firearms

- 09: Cartridge and Shotshell Examination

- 10: Characterization and Evaluation of Fired Projectiles

- 11: Bullet Comparison and Identification

- 12: Gunshot Residue and Distance Determination

- 13: Toolmark Identification

- 14: Communicating Results

- Resources

Centerfire

Home > Small Arms Ammunition > Cartridge Case Manufacture > Centerfire

Similar to rimfire cases and metal bullet jackets, most centerfire cases start as cups. Since the raw sheet brass required for these cases is often thicker than that used for rimfire cases, preformed cups are frequently purchased by the manufacturer.

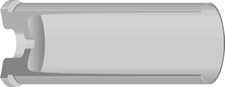

Cross section of a cartridge case

Drawing is the most widely used method in the manufacture of brass cases. It reduces diameter and increases length and is the best method for case fabrication. There is little difference in tooling between case-drawing dies and those used to make bullet jackets.

Depending on the length of the finished case, the cup may be drawn from one to five times. For cases requiring three to five draws, an intermediate stress relief heat treatment may be applied to keep the material ductile. The dies and punches maximize the diameter and length and fully shape the cavity. This profile defines the wall thickness of the finished part. The case will be thinnest at the mouth to allow flexibility for holding the bullet. To withstand firing pressures, the walls will be thickest at the closed end.