- 01: Introduction

- 02: History

- 03: Propellants, Firearms, and Ammunition Development

- 04: Modern Firearms Manufacture

- 05: Small Arms Ammunition

- 06: Evidence Handling Procedures

- 07: Equipment and Instrumentation

- 08: Examination of Firearms

- 09: Cartridge and Shotshell Examination

- 10: Characterization and Evaluation of Fired Projectiles

- 11: Bullet Comparison and Identification

- 12: Gunshot Residue and Distance Determination

- 13: Toolmark Identification

- 14: Communicating Results

- Resources

Effects of Firing

Home > Characterization and Evaluation of Fired Projectiles > Microscopic Marks >Effects of Firing

Some effects of firing result in microscopic marks of value to the firearm examiner:

- Shaving (shearing) is the cutting of metal from the surface of a bullet due to cylinder misalignment in a revolver. A large amount of shaving may leave a void in the bearing surface of a bullet, which may not receive rifling impressions.

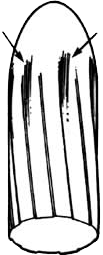

- Skid marks (slippage) form on the bearing surface of bullets as they enter the rifling of the barrel before the bullet engages the rifling. Skid marks are typically produced by revolvers and have the appearance of widening the land impressions at the nose of the bullet. Taking measurements in this area should be avoided; base measurements are more accurate.

- Flared bases of bullets fired from short-barreled handguns or bullets with deep base cavities are subject to expansion after leaving the barrel of a firearm. Measuring a flared base would be misleading; the better protected base normally provides the best dimensional data.

- Blowby is the escaping of gases past a fired bullet while the bullet is still in the barrel. These high pressure gases are at a very high temperature and can melt or etch the bearing surface of plain lead bullets. As a result, the width of rifling impressions can be seriously degraded and appear very blurry and indistinct.

- Barrel leading (metal fouling) is the accumulation of lead or bullet jacket material in the bore of a firearm due to the passage of bullets. This condition may preclude obtaining reliable land and groove dimensions.

- Corroded/rusted barrels occur due to poor care and maintenance and affect bullet bearing surfaces in the same way as metal fouling or leading.

- Lead smears may be deposited on the surface of bullet jackets, obscuring the edges of the land and groove impressions.

These can be removed using a solution containing - 10cc of glacial acetic acid,

- 2cc of 30 percent hydrogen peroxide,

- 70cc of distilled or deionized water.

Skid marks