- 01: Introduction

- 02: History

- 03: Propellants, Firearms, and Ammunition Development

- 04: Modern Firearms Manufacture

- 05: Small Arms Ammunition

- 06: Evidence Handling Procedures

- 07: Equipment and Instrumentation

- 08: Examination of Firearms

- 09: Cartridge and Shotshell Examination

- 10: Characterization and Evaluation of Fired Projectiles

- 11: Bullet Comparison and Identification

- 12: Gunshot Residue and Distance Determination

- 13: Toolmark Identification

- 14: Communicating Results

- Resources

Crimping

Home > Small Arms Ammunition > Shotshell Assembly > Loading > Crimping

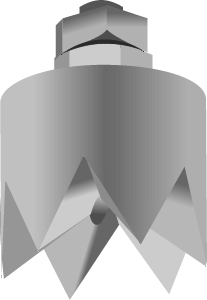

Crimp starter

Shotshells can be secured with folded crimps or roll crimps. Folded crimps are informally called pie crimps because of the shape of the sections as viewed on the end of the case. Folded crimps predominate; the roll crimp is reserved for special loads, including buckshot and slugs . Regardless of the crimp type, crimping paper or plastic shotshell cases must be performed in stages.

A crimp starter is a short die (or two dies in sequence) with internal angled ribs that make small bends in the case mouth. If a two-stage starter is used, the case is quickly moved from the first to the second stage before the case mouth springs back. The second die extends the full length of the fold and forces the resulting segments inward. At this point, the segments are within forty-five to sixty degrees (from the vertical) of meeting level in the middle.

The crimper is a die containing a concentric punch and is sized to fit the outside of the case. When the case is captured in the die, the flat-faced punch pushes on the folds, forcing them to meet (as close as possible) in a single plane. This tooling is also designed to push the finished folded crimp below the new edge of the case, helping to lock the crimp in place.

As an option, a crimp finisher may be employed to give a slight taper to the case mouth for smoother feeding in repeating shotguns. This device is a spinning cup (with tapered inside walls) that rotates fast enough to soften plastic or wax-impregnated paper. Mild heating produced by the friction of the rotation helps the case mouth to retain its shape.

Some folded crimps in plastic shotshells are further sealed for moisture resistance by the application of wax or another thermal sealant directly on the center of the crimp. Cases may be thermally sealed by applying heat to the center of the folds, welding the segments together. Thermal sealing is more commonly found in inexpensive loads where the cases are not likely to be reused because the heat seal damages the case mouth.

Roll crimping can be used to hold an overshot wad or a slug. This must also be performed in stages and is seldom accomplished on high-speed equipment. The simplest roll crimper is a spinning die with an internal shape that duplicates the desired cross-sectional profile of the finished case mouth. Lowered slowly onto a case mouth, the spinning action of the die heats the case material enough for it to move. As the die lowers, the mouth is forced inward and over a shoulder in the roll crimper, completing the required 180-degree turn.