- 01: Introduction

- 02: History

- 03: Propellants, Firearms, and Ammunition Development

- 04: Modern Firearms Manufacture

- 05: Small Arms Ammunition

- 06: Evidence Handling Procedures

- 07: Equipment and Instrumentation

- 08: Examination of Firearms

- 09: Cartridge and Shotshell Examination

- 10: Characterization and Evaluation of Fired Projectiles

- 11: Bullet Comparison and Identification

- 12: Gunshot Residue and Distance Determination

- 13: Toolmark Identification

- 14: Communicating Results

- Resources

Stamping

Home > Modern Firearms Manufacture > Gross Metal Forming Operations > Stamping

In many ways, stamping is a subset of forging applied to thin, cold stock. An example outside the firearms industry is a metal car-body panel. Large sheets of flat metal are placed in a stamping press carrying dies that are the negative of the final part. In one blow, the cold sheet metal assumes the shape forced by the die design.

Typically, stamping is used to form thinner firearms parts that are not load-bearing, such as magazines and trigger guards. The U.S. caliber .30 M1 Garand rifle has a number of stamped parts, including those making up the trigger guard and magazine floorplate. For such military arms, where function takes precedence over form and beauty, stampings have been successfully used to produce the lower and upper receiver units for submachine guns and some battle rifles. The upper housing that carries the bolt in the UZI submachine gun is die-cut from a single sheet of metal, then folded into its final “box” shape in a stamping press. The corners are then welded to finish the unit.

Stamped trigger guard and floorplate

on an inexpensive 22LR rifle

Early variants of the famed (or to some people, infamous) Automat Kalashnikov (AK-47) had stamped receivers. The receiver consisted of a right- and left-hand stamped unit that were secured with machined spacer blocks and screwed or riveted together. Most AK-47s were produced with milled receivers.

Some SIG SAUER® pistols have slides (the upper reciprocating unit in a semiautomatic handgun) that are stamped. The material is very heavy and many observers would fail to immediately identify the part as stamped. After stamping, the slide is formed into an inverted “U”, and a plate is precision welded to the front to support the barrel. A machined breechblock is pinned through at the rear. The result is a pistol of high quality and reliability.

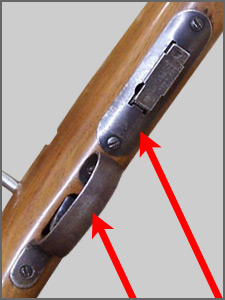

A precision subset of stamping is fine blanking. Fine-blanking can produce smaller parts like triggers, hammers, or the shell latches for repeating shotguns to tolerances that rival machined parts. The limitation is material thickness. This means fine-blanking is usually seen in parts that are essentially flat and under 1/4 inch (6 mm) thick. However, several identical fine-blanked parts can be stacked to produce a thicker part. A common example is the latch in a .22 caliber Ruger Standard Auto pistol that secures the barrel extension to the frame. Three blanks are stacked to produce a relatively hefty latch.

Most firearm examiners will see stamped construction in military, law enforcement, and commercial firearms.